Home > Lean IT vs Lean Management: Key Differences and Synergies

In the Swiss economic landscape, where companies continuously seek to strengthen their competitiveness, Lean Management and Lean IT have emerged as essential approaches. But what is the real difference between these two methodologies? How do they complement each other to transform your organization? Whether you are the head of a family-owned SME, CIO of a Geneva-based bank, or an operations director, understanding these approaches has become crucial. In this article, we will break down the fundamental principles of Lean Management and Lean IT, explore their key differences, and discover how to combine them effectively to create true organizational synergy.

Lean Management is not just a management method. It is a true philosophy that has revolutionized the industrial world since the 1950s. But where exactly does this globally recognized approach originate, and how does it adapt to the Swiss economic ecosystem?

It all began in Toyota factories in Japan in the 1950s with Taiichi Ohno and Shigeo Shingo. Confronted with post-war economic constraints, Toyota needed to produce more efficiently using fewer resources. This led to the birth of the renowned Toyota Production System (TPS), the ancestor of modern Lean Management. A philosophy that strongly resonates with Swiss culture, known for precision and optimization.

Key figure: According to a study from the Lean Enterprise Institute, companies that adopt Lean Manufacturing report an average of 25% improvement in productivity. For Swiss SMEs, often family-owned and quality-focused, this improvement can be decisive.

Source: Amelioration.fr – Lean Enterprise Institute Study

The term “Lean” itself only appeared in the 1990s, popularized by James P. Womack and Daniel T. Jones in their groundbreaking book “The Machine That Changed the World.” This book demonstrated how Lean manufacturers achieved productivity levels 30% higher than traditional manufacturers. This marked the beginning of a worldwide revolution that quickly influenced Swiss watchmaking, the pharmaceutical industry, and leading technology companies.

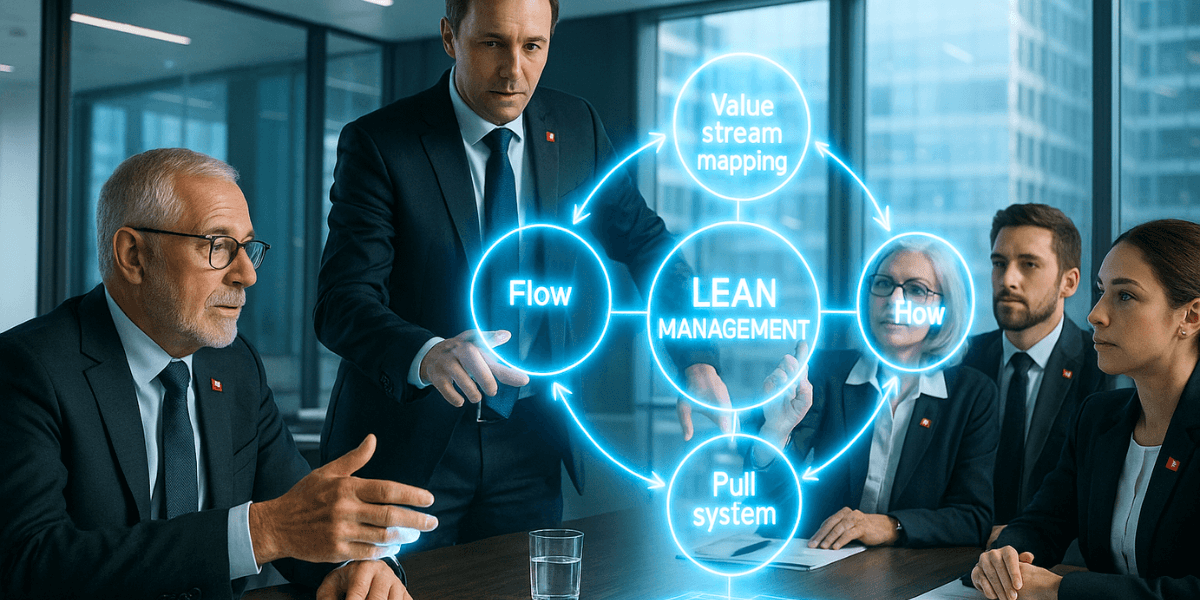

Lean Management is based on five simple yet powerful principles. Think of them as the five pillars of a Swiss chalet: remove one, and everything risks collapsing.

1. Define value from the customer’s perspective: Everything starts here. What truly creates value for your customer? In a watchmaking factory in Vaud, for example, value may be the precision of the movement and the quality of the finishes. Everything else? Potential waste. This same discipline is what you find at Rolex or Patek Philippe in Geneva.

2. Map the value stream: This consists of visualizing every step of the process from start to finish. Value Stream Mapping helps identify where waste and bottlenecks occur, just like planning a precise route through the Alps.

3. Create continuous flow: The objective? Eliminate interruptions and waiting times to ensure the product moves smoothly from one step to the next. It’s like a mountain stream: the water flows without obstacles, consistently and efficiently.

4. Implement a pull system: Produce only what is needed, when it is needed. The famous Just-in-Time method can reduce inventory by up to 60%, according to a study from the University of Cambridge. For Swiss SMEs where every franc counts, this is significant.

Source: Amelioration.fr – University of Cambridge Study

5. Pursue perfection (Kaizen): Kaizen, which means “continuous improvement” in Japanese, is the heart of Lean. It is never “good enough.” There is always room for improvement, step by step, day after day, a philosophy that naturally aligns with Swiss standards of excellence.

At the heart of Lean Management lies the concept of Muda, the Japanese word for “waste.” Traditionally, seven types of waste are identified (often with an eighth added):

Measurable impact: Companies that adopt Lean Management report productivity improvements of 20% to 30%, with manufacturing lead times reduced by up to 50%.

Source: Intense Plus – Lean Management Statistics

While Lean Management transformed the industrial sector, Lean IT is now revolutionizing information systems. And that’s timely: with the rapid digitalization of Swiss companies, CIOs are at the forefront. But be careful, it’s not simply Lean applied to IT. It is far more nuanced.

Lean IT emerged in the early 2000s, popularized by Mary and Tom Poppendieck in their book “Lean Software Development.” The findings were alarming: only 16% of IT projects are completed on time and within budget, according to IT for Business.

Source: Symétrie Consulting – IT project statistics

Why was IT in such urgent need of Lean? Unlike industrial production, IT faces unique challenges: exponentially increasing technical complexity, rapid obsolescence, intangible products that are difficult to measure, and massive variability across projects. These are challenges well known to CIOs in Swiss cantonal banks or insurance groups.

Lean IT is based on five core principles tailored to the digital context:

Define IT value from the user’s perspective: An IT system only has value if it truly helps users accomplish their tasks more effectively. A complicated application is waste, no matter how advanced its technology. Employees in Geneva’s banking sector or Basel’s pharmaceutical industry need tools that are simple and efficient.

Optimize workflow: In IT, workflows are informational. The goal is to eliminate redundancies, unnecessary approvals, and faulty testing environments, just as one would optimize a watchmaking production line.

Eliminate IT-specific waste: Unused code, unnecessary features, approval wait times, technical over-engineering, technical debt… IT waste has its own particular shapes.

Promote continuous improvement in IT: Agile retrospectives, the PDCA cycle applied to development, progressively automating tests… Continuous improvement sits at the heart of Lean IT.

Build a culture of agility: Autonomous teams able to adapt quickly to technological change and business needs. An agility that fits the Swiss tradition of adaptation and innovation.

In the world of information technology, waste takes particular forms. For a modern CIO, identifying them is crucial:

Lean IT and DevOps are closely linked. In fact, DevOps can be seen as Lean Management instantiated for IT activities. Consultants at OCTO explain that “DevOps best practices are instantiations of Lean Management for delivery, integration, testing, deployment, and run observability.”

Source: OCTO Talks – DevOps and Lean

Continuous improvement in DevOps comes from reducing batch size, that is, delivering smaller “batches” of code more frequently. This is precisely the pull-flow principle adapted to software development.

Now that we’ve explored both approaches, what are their concrete differences? For a Swiss business leader, understanding these distinctions is crucial to know when and how to apply each.

| Criterion | Lean Management | Lean IT |

|---|---|---|

| Scope | Entire organization, all sectors | Specific to information systems and the IT department |

| Type of flow | Physical and material flows | Information and digital flows |

| Nature of products | Tangible, manufactured goods | Intangible products (software, IT services) |

| Main tools | 5S, physical Kanban, SMED, TPM | CI/CD, digital Kanban, Infrastructure as Code |

| Roles involved | Managers, operators, process engineers | CIO, developers, architects, DevOps |

| Key metrics | OEE (TRS), takt time, inventory turnover rate | Deployment frequency, MTTR, lead time for changes |

| Relationship to change | Emphasis on standardization and stability | Continuous innovation and adaptation |

Lean Management applies across an entire organization: production, logistics, administration, HR… It’s a global approach. A watch manufacturer or a pharmaceutical group will apply Lean across all workshops and departments.

Lean IT, by contrast, focuses exclusively on information systems and the IT department. It’s a necessary specialization given the peculiarities of the digital world, well known to IT leaders in our cantonal banks and insurance companies.

In classic Lean Management, we deal with physical flows: incoming raw materials, work-in-process, outgoing finished goods. It’s tangible, visible, and directly measurable.

In Lean IT, flows are intangible: data, source code, business information, technical knowledge. How do you measure the “quality” of a line of code? That’s the complexity IT teams must manage.

Lean Management uses physical tools: Kanban boards with cards, 5S workplace organization, quick changeovers (SMED) on machines. Methods we see in precision mechanical workshops.

Lean IT favors digital tools: CI/CD pipelines (Jenkins, GitLab), digital Kanban (Jira, Trello), Infrastructure as Code (Terraform, Ansible), automated monitoring (Prometheus, Grafana). Modern tools tailored to the software world and widely used by Romandy tech startups.

Here’s where it gets really interesting for your company. Lean Management and Lean IT are not in competition. They’re complementary. And when combined intelligently, they create exceptional synergy.

Lean Management optimizes business processes to satisfy the external customer. Lean IT optimizes information systems to satisfy the internal customer (employees). But in a modern organization, the two are inseparable!

Take the example of a Geneva private bank. The account opening process must be smooth (Lean Management) AND supported by a high-performing IT system (Lean IT). If either one fails, the entire customer experience collapses. The same logic applies to an insurance company or a retail group.

Continuous improvement cannot be siloed. A shared Kaizen culture across the whole organization, with joint IT/Business retrospectives, creates a powerful dynamic.

According to Mark Cruth, Modern Work Coach at Atlassian: “Many methodologies and models find their roots in Lean, which requires a Lean mindset. That’s why you’ll find Lean principles woven into every modern way of working.”

Source: Atlassian – Lean principles

Operational waste (Lean Management) + IT waste (Lean IT) + interface waste (IT/Business communication) = a holistic view of organizational efficiency.

Concrete result: A study of 610 companies shows that Lean deployment can double productivity while reducing manufacturing lead times and inventory by 90%.

Source: Blue Lean – Demeter & Matysuz study, International Journal of Production Economics

Here’s the wonderful paradox: Lean Management brings standardized processes and stability. Lean IT brings agility and rapid adaptability. Combine them, and you get a stable platform that enables innovation. It’s like having solid foundations to build higher.

Value Stream Mapping (VSM): Whether you are mapping a production line or a software development process, VSM remains the universal tool to visualize value flows and identify waste.

Kaizen (Continuous Improvement): Kaizen workshops in production, Agile retrospectives in IT… it’s the same continuous improvement principle applied everywhere. A philosophy deeply rooted in Switzerland’s culture of excellence.

The 5 Whys: A root-cause analysis technique applicable to both a machine breakdown and a critical IT incident. Simple yet extremely effective.

PDCA (Plan-Do-Check-Act): The universal continuous improvement cycle, applicable in all contexts. Plan, do, check, adjust. Then repeat.

5S (Sort, Set in Order, Shine, Standardize, Sustain): a method for organizing the physical workspace. In a Neuchâtel watchmaking workshop, every tool has its precise place.

SMED (Single-Minute Exchange of Die): a quick-change technique to reduce machine downtime. Essential in Swiss manufacturing.

Poka-Yoke: physical mistake-proofing systems. Mechanical fail-safes that prevent assembly errors.

CI/CD pipelines: automation of continuous integration and continuous delivery/deployment. DevOps teams in Romandy use Jenkins, GitLab CI, or Azure DevOps to automate releases.

Infrastructure as Code (IaC): managing IT infrastructure like source code. Terraform and Ansible are go-to tools.

Monitoring & Observability: Prometheus, Grafana, ELK Stack… essential tools to detect issues before they impact users.

Test automation: Selenium, JUnit, Pytest… automating tests enables faster delivery with higher quality.

OEE (Overall Equipment Effectiveness): a measure of an asset’s overall effectiveness. For a Swiss plant, an OEE above 85% is considered excellent.

Takt time: the production pace needed to meet customer demand. It’s the heartbeat of your production.

Lead time: total time from order to delivery. Lean companies aim for a reduction of 50% or more.

Inventory turnover rate: how many times your stock turns per year. The higher it is, the less capital you tie up.

Deployment Frequency: how often do you deploy to production? High-performing DevOps organizations deploy multiple times per day.

Lead Time for Changes: the time between a code commit and its deployment to production. Top-performing teams measure this in hours, not weeks.

MTTR (Mean Time To Repair): the average time required to resolve an incident. For banking IT departments, every minute counts.

Change Failure Rate: the percentage of deployments that cause incidents. Elite organizations maintain this rate below 5%.

Source: State of DevOps Report – Google Cloud

Let’s be honest: technology and processes are the easy part. The real challenge? People. And in the Swiss context, with our culture of consensus and strong attachment to tradition, change management is absolutely critical.

On the IT side: your developers and operations teams may fear a loss of technical autonomy. “We’re going to become a code factory!” is a common reaction. They must be reassured: Lean IT is about giving them more autonomy, not less.

On the Business side: mistrust towards IT is often deeply rooted. Years of delayed projects and unmet promises have created a divide. Rebuilding trust takes time.

Middle management: managers may perceive Lean as a threat to their authority. Decision decentralization and team empowerment challenge traditional hierarchies.

Transparent communication: explain the “why” before the “how.” Swiss professionals value clarity and honesty. No corporate jargon.

Visible quick wins: nothing is more convincing than tangible results. Start with a small pilot project that quickly demonstrates benefits. A 30% reduction in lead time on a critical process? That speaks to everyone.

Targeted training: invest in skills development. For IT teams: DevOps, Agile, automation training. For business teams: workshops on Lean principles, VSM, and Kaizen.

Recognition of efforts: celebrate successes, even small ones. Highlight teams that make progress.

Real transformation doesn’t come from tools or processes. It comes from deep cultural change. Here is how to embed it:

Shared values: respect for people, continuous improvement, waste elimination, customer focus. These values must become the common foundation across IT and Business.

Common language: when everyone speaks in terms of “value streams,” “waste,” and “Kaizen,” organizational silos begin to disappear. Lean vocabulary becomes the language of efficiency.

Unifying events: organize Kaizen weeks where IT and Business jointly work on a process. An intensive improvement week with tangible results. These events build lasting bonds.

Committed leadership: leadership must embody Lean. If the CEO participates in Gemba walks, and the CIO personally leads retrospectives, the message is clear: this is serious and driven from the top.

Learn from the mistakes of others. Here are the most frequent pitfalls seen in Lean transformation projects in Switzerland:

Initial enthusiasm often leads to launching ten initiatives simultaneously. The result: diluted efforts, overwhelmed teams, and nothing truly completed. It is far better to fully transform one process than to partially improve ten.

Focusing solely on tools and processes while forgetting that they will be used by people. Without team buy-in, your transformation rests on shaky foundations.

What works at Toyota or a Silicon Valley startup cannot be applied directly to a Swiss SME. Be inspired, but always adapt to your local context.

The first months are challenging. Results take time to appear. The temptation to abandon the effort is strong. The organizations that succeed are those that stay the course. Lean is a marathon, not a sprint.

“You can’t improve what you don’t measure.” Without precise indicators, you are flying blind. Define your KPIs from the start and track them rigorously.

The world is evolving, and so is Lean. What trends are shaping the future of Lean Management and Lean IT?

AI will profoundly transform Lean. Imagine an AI system that automatically identifies waste in your processes, suggests real-time optimizations, and predicts failures before they occur. This is no longer science fiction, it’s already happening among industry pioneers.

For companies, the challenge is to integrate AI without losing the human focus. AI should amplify collective intelligence, not replace it.

Connected factories, digital twins, industrial IoT… all these technologies naturally align with Lean principles. They enable real-time visibility, total traceability, and continuous optimization.

Precision manufacturers that combine traditional know-how with 4.0 technologies hold a decisive competitive edge.

“Green Lean” is emerging as a major trend. Eliminating waste also means reducing environmental impact. Optimizing flows means consuming less energy. Lean and sustainability are naturally aligned.

For companies committed to environmental responsibility, this is a highly beneficial convergence.

What should you take away from all this?

Firstly, these two approaches are complementary, not competitive. Lean Management optimizes your operational and physical processes, while Lean IT optimizes your information systems and digital workflows. In a world where physical and digital are inseparable, you need both.

Secondly, Lean is not just a set of tools or methods. It is a philosophy, a mindset, a culture. It is about putting the customer at the center, relentlessly eliminating everything that does not create value, and continuously improving day after day.

Thirdly, the numbers speak for themselves: 25% increase in productivity, 50% reduction in lead times, 90% reduction in inventory, and a doubling of overall productivity. These are not hypothetical promises, they are measured and documented results.

What is the main difference between Lean Management and Lean IT?

Lean Management applies across the entire organization with a focus on physical and material flows, while Lean IT focuses exclusively on information systems and digital workflows. Both share the same philosophy of eliminating waste and are highly complementary.

How long does it take to see the first results of a Lean transformation?

Initial quick wins can be visible within 4–6 weeks. However, a deep Lean transformation typically takes 12 to 18 months to become truly embedded in the company culture.

Is Lean suitable for Swiss SMEs or only for large corporations?

Lean is especially suitable for Swiss SMEs! They are more agile and can adapt quickly. Efficiency gains (20–30% increased productivity, 50% shorter lead times) have a direct and measurable impact on profitability.

Can Lean IT be combined with other methodologies such as Agile or ITIL?

Absolutely! Lean IT naturally complements Agile and ITIL. These methodologies are not in conflict: ITIL provides robustness, Lean IT delivers efficiency, and Agile brings flexibility.

What investments are needed to begin a Lean transformation?

For a Swiss SME with 100 employees, the initial investment typically ranges from CHF 30,000 to 50,000 in the first year (training, coaching, tools). The ROI is generally excellent: most companies recover their investment within 6 to 12 months thanks to efficiency gains.

ITTA is the leader in IT training and project management solutions and services in French-speaking Switzerland.

Our latest posts

Subscribe to the newsletter

Consult our confirmed trainings and sessions

Nous utilisons des cookies afin de vous garantir une expérience de navigation fluide, agréable et entièrement sécurisée sur notre site. Ces cookies nous permettent d’analyser et d’améliorer nos services en continu, afin de mieux répondre à vos attentes.

Monday to Friday

8:30 AM to 6:00 PM

Tel. 058 307 73 00

ITTA

Route des jeunes 35

1227 Carouge, Suisse

Monday to Friday, from 8:30 am to 06:00 pm.